Curtain walls provide not only structural benefits but also aesthetic appeal. When paired with powder coating, these systems offer a durable, visually striking, and eco-friendly finish. In this article, we'll explore how to effectively use powder coating for high quality curtain wall systems, detailing the process, benefits, and best practices for achieving a superior facade.

What Is Powder Coating and Why Use It?

Powder coating is a dry finishing process where a free-flowing, electrostatically charged powder is applied to a surface. Unlike traditional liquid paint, it cures under heat or ultraviolet light to form a resilient, thick film. This method is particularly suited for curtain walls, as it provides:

- Enhanced Durability: Powder coatings resist chipping, scratching, and corrosion.

- Eco-Friendliness: With little to no volatile organic compounds (VOCs), it meets strict environmental standards.

- Aesthetic Versatility: Available in a wide array of colors and finishes, powder coating can be tailored to match modern architectural designs.

Key Benefits for Curtain Walls

Using powder coating on curtain walls results in a finish that stands up to harsh weather conditions and the test of time. Key advantages include:

- Long-Lasting Protection: Provides superior resistance against UV light, moisture, and temperature variations.

- Low Maintenance: The robust finish reduces the need for frequent touch-ups and repairs.

- Energy Efficiency: The coating can improve thermal insulation, contributing to better energy performance for the building.

- Visual Appeal: Powder coated finishes offer uniform, high-gloss or matte textures that elevate the building's facade.

Step-by-Step Process for Powder Coating Curtain Walls

1. Surface Preparation

Proper preparation is crucial for optimal adhesion and durability. Steps include:

- Cleaning: Remove all dirt, grease, and contaminants from the metal surface.

- Surface Treatment: Use chemical or mechanical methods (e.g., sandblasting or acid etching) to create a slightly rough texture that improves powder adhesion.

- Preheating (if required): Preheat the metal to promote even coating and prevent defects during application.

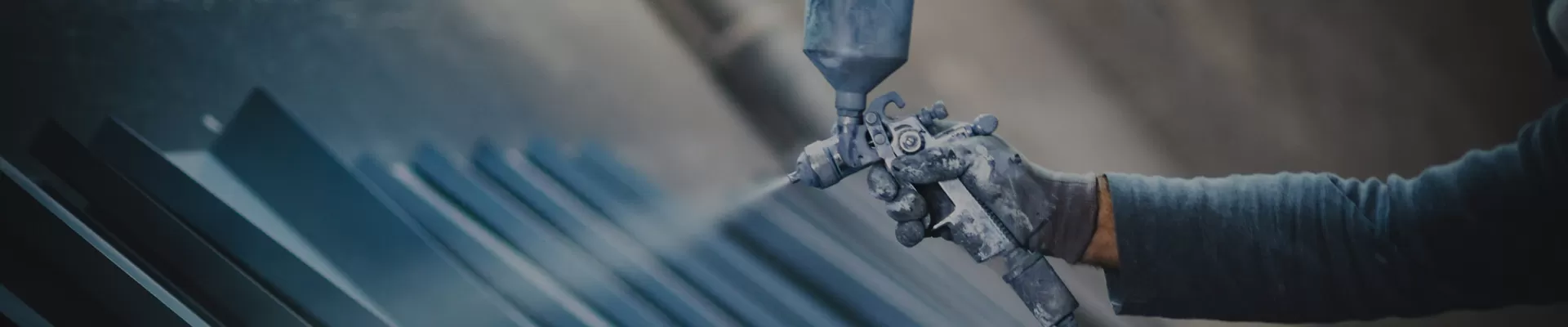

2. Powder Application

The powder is applied using an electrostatic spray gun:

- Electrostatic Charging: The powder particles are electrically charged, ensuring they uniformly adhere to the grounded curtain wall panels.

- Even Distribution: Multiple passes may be necessary to achieve the desired thickness without runs or sags.

3. Curing Process

Curing transforms the powder into a hard, continuous film:

- Thermal Curing: The coated panels are placed in an oven, typically at temperatures between 160°C and 200°C, for a specified duration to crosslink the polymer.

- UV Curing (Optional): For heat-sensitive substrates, UV-curable powders can be used, which significantly reduce cure times and energy consumption.

Best Practices for Achieving a High Quality Finish

- Quality Control: Monitor each step from surface preparation to curing. Regular inspections help catch imperfections early.

- Powder Selection: Choose a powder coating formulation specifically designed for architectural applications. Consider factors like weather resistance, color stability, and mechanical durability.

- Consistent Application: Use calibrated equipment to ensure uniform powder distribution. Automated spray systems can enhance consistency, especially on large panels.

- Environmental Considerations: Ensure proper ventilation and dust control during application and curing to maintain a clean, safe work environment.

Practical Considerations for Curtain Wall Applications

When implementing powder coating on curtain walls, keep these factors in mind:

- Design Integration: Work closely with architects to select a finish that complements the overall design and meets the performance requirements.

- Weather Exposure: Consider the local climate and environmental conditions. Powder coatings for curtain walls must withstand extreme temperature changes, humidity, and UV exposure.

- Maintenance and Repair: Although powder coatings are durable, plan for periodic inspections and maintenance to address any wear or damage.

Conclusion

Powder coating offers a modern, robust solution for finishing curtain walls, combining aesthetic flexibility with unmatched durability. By following a structured process—from meticulous surface preparation to precise application and curing—you can achieve a high quality, long-lasting finish that enhances both the appearance and performance of your architectural facade. Whether you're aiming for a sleek, modern look or a bold statement, powder coating is an excellent choice for elevating curtain wall systems to new heights.

For more detailed guidance and technical support, consider consulting with powder coating specialists and equipment manufacturers who can tailor solutions to your specific project needs.